Gas detection drone to help inspection of oil and gas pipelines Leave a comment

Gas detection drone For petrochemical companies, in order to prevent oil and gas pipeline leakage, regular inspections of oil and gas pipelines are an important part of their safety work. However, due to the long length of the general oil and gas pipelines and the complicated terrain along the route, the traditional pure manual inspections are quite limited, which not only has a large workload, high labor costs, low inspection efficiency, but also the inspection time limit is easily limited, and the quality is difficult Take control. Aiming at the pain points of pure manual inspections, the use of drones equipped with “smell smell” gas monitoring equipment can greatly assist the inspection of oil and gas pipelines. Recently, Kofi Technology successfully delivered a set of “smell-smelling” gas mobile monitoring system based on drone to a quality supervision institution in Guangzhou through a supplier, which was applied to the inspection of oil and gas pipelines.

At the work site, the inspectors controlled the drone to carry the “Smell Smell” lift-off, and scanned the pipeline along the pipeline within 3m above the oil and gas pipeline. At the same time, they paid close attention to the methane and VOCs gas concentration gradient changes displayed in the Sniffer 4D Mapper software.

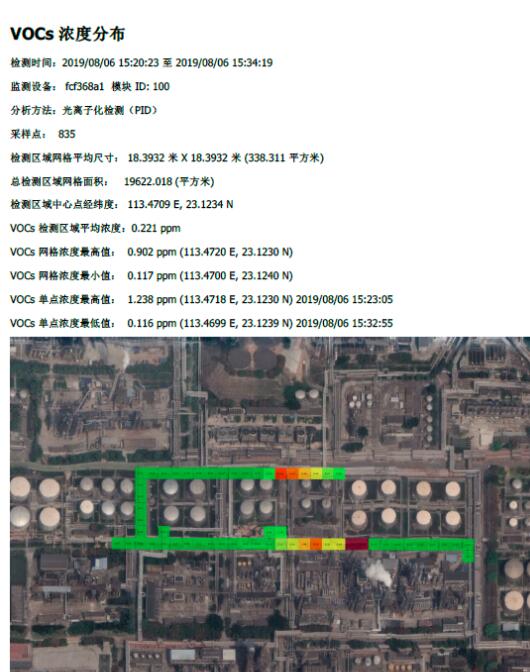

The following figure is a two-dimensional grid concentration distribution map of VOCs generated in real-time in the mapper software. It can be seen that the VOCs concentration in three of these areas is significantly higher, that is, the smart smell quickly identified three key areas, which greatly improved the efficiency of investigation.

Gas detection drone Due to the dense distribution of oil and gas pipelines, after preliminary detection of high-concentration areas, inspectors need to further inspect the high-concentration areas by combining images and video information taken by drones.

According to this pipeline inspection case, it can be seen that compared with the traditional purely manual inspection method, the “spirit smell” gas mobile inspection system based on drones has multiple advantages. When combined with the manual inspection method, it can greatly Improve the quality and efficiency of pipeline inspections: First, it can break through the constraints of terrain and other factors, flexibly choose the scanning path and inspection location, reach places that are difficult for inspectors to reach, and cover the inspection area on a large scale;

Second, the preparation time is short, the deployment speed is fast, time and labor costs are saved, the safety risk of inspection personnel is reduced, and emergency situations are detected, reported, and handled in a timely manner; It can directly obtain the gas concentration distribution and image and video information of the inspection pipeline, and transmit it to the on-site inspection personnel, rear management personnel, and technical experts in real time, providing important references for solving difficult problems and making comprehensive decisions; The supporting software can output the task report with one click, and the report can be quickly generated on site after the task is completed. In addition to the key information such as detection time, grid / single point maximum concentration and corresponding latitude and longitude positioning, a very intuitive grid map of gas concentration is also attached. Not only can it be used as the basis for reporting and further manual verification, but also the task report can be regularly sorted and compared to verify the effectiveness of the treatment of hidden dangers. It is helpful for related enterprises to grasp the overall situation of oil and gas pipelines, which is efficient, intuitive and convenient.

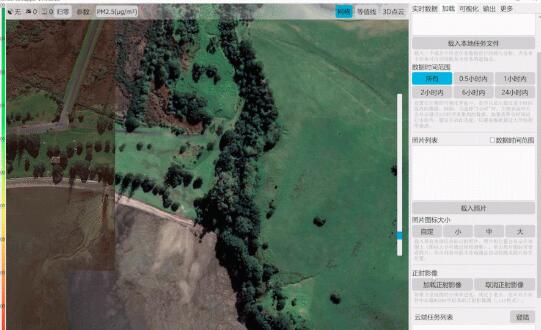

Fifth, the software can load the orthophoto map of the factory area (because satellite maps usually have low resolution and it is difficult to reflect all details of the factory area), satellite map + high-definition orthophoto map + gas distribution map, three layers are more helpful Identify problems accurately for users.